We have applied Casted SiC to make liners for desanding systems. The novelty material which is characteristic of high wear resistance (both chemical erosion and mechanical wearing) and low weight, has reduced tremendous down-time for repair and maintenance. We have experience to make such liners in a range of shapes and sizes: hydrocyclones, inlets, cones ect. with OD ranging 50~800mm and Length 100~2000mm.

Here is the life-time contrast of Casted SiC vs Duplex Stainless Steel (Duplex SS), Stellite Alloy (SA) and 4101 Tool Steel (4101 CS):

|

Compressor Vessel |

|

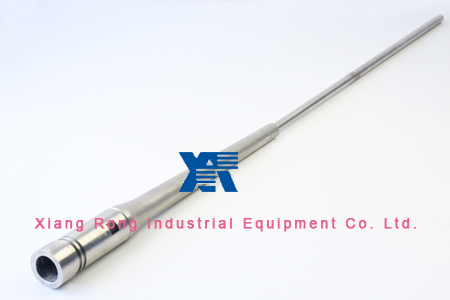

We have pioneeredly developed Deoiling Hydrocyclone Liners from Tungsten Carbide (TC), a much more wear resistant material than such traditional materials as Duplex SS and other alloys, for the offshore oil industry. As the primary spare parts for the separating system used for recovery of oil from produced water streams, our Deoiling Hydrocyclone Liners exhibit the following benefits: |

|

·Compact Design |

|

| ·Cost effective with low OPEX costs |

| ·No moving parts with little maintenance required |

| ·Highly consistent performance |

| ·Proven ultra wear resistance |

| ·Suitable for use on FPSO's ect |

| |

| |

|

| TC Inlet | |

|

Aside from Tungsten Carbide, we offer cyclone liners made from Duplex Stainless Steel in a range of sizes for different budgets.

No. |

Mateiral |

Density (g/cm3) |

Hardness (HV) |

Strong Acid Alkli |

|

1 |

Casted SiC |

3.01 |

2000 |

III |

|

2 |

Duplex SS 2205 |

7.80 |

《320 |

II |

|

3 |

Stellite Alloy 6 |

8.46 |

396 |

II |

|

4 |

4101 TS |

7.81 |

220 |

I |

Excellent: III Good: II Ordinary: I | |